How To Convert FEM and ASME Duty Cycle Ratings

Conversion Guide for North American ASME/European FEM

Note: The information below is intended as a brief overview of duty cycles and their respective European and North American classifications. The formulas for obtaining duty cycles are much more complicated than we go into in this article, and require a significant amount of additional information.

Duty rating is one of the most important factors in the overall crane calculation. It is important for safety, as it lets you know exactly when you should be doing certain checks and maintenance and commercially as well as you as you want to be able to equip yourself with a hoist that is designed and built to withstand the type of usage you intend to put it through.

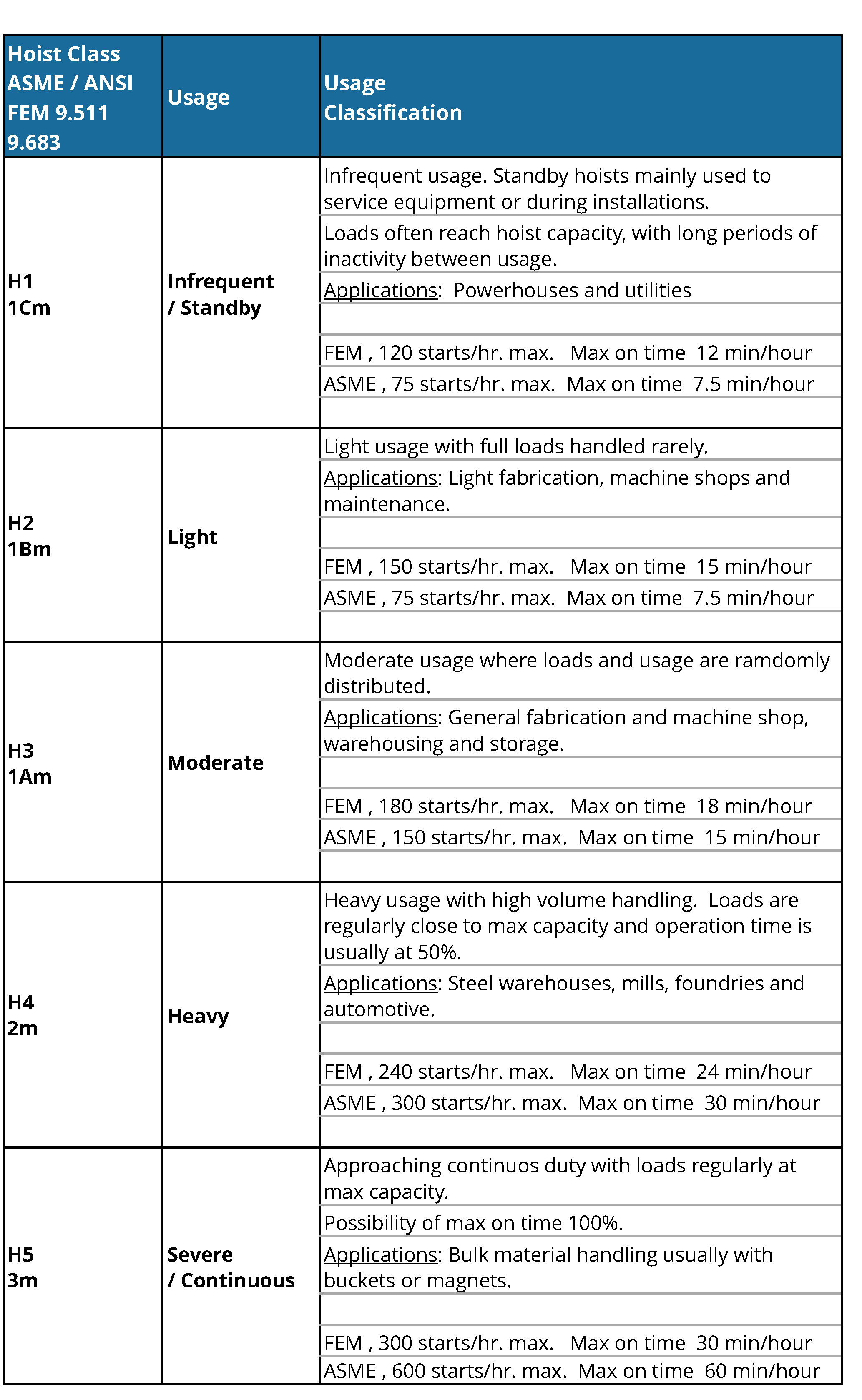

It is important to understand duty cycles and how they are rated. We will be looking at two standards, and how they compare: FEM 9.511 and 9.683 from the European Federation of Material Handling, and ANSI/AMSE HST4 from the American Society of Engineers. Although measuring similar variables, each standard uses slightly different formulas to rate their duty so it always important before you make any selection to take as much information about the application and calculate independently.

As you can see, its hard to line these two standards up exactly, especially on the very light and very heavy duty cycles but in the middle, H3 and H4 they more or less, tend to agree. So what is it exactly that these standards are measuring? There’s a lot more to it, but the basics are:

- number of lifts per hour

- number of starts per hour

- frequency max weight is lifted

- distance the load is raised and lowered

- average and maximum weight lifted

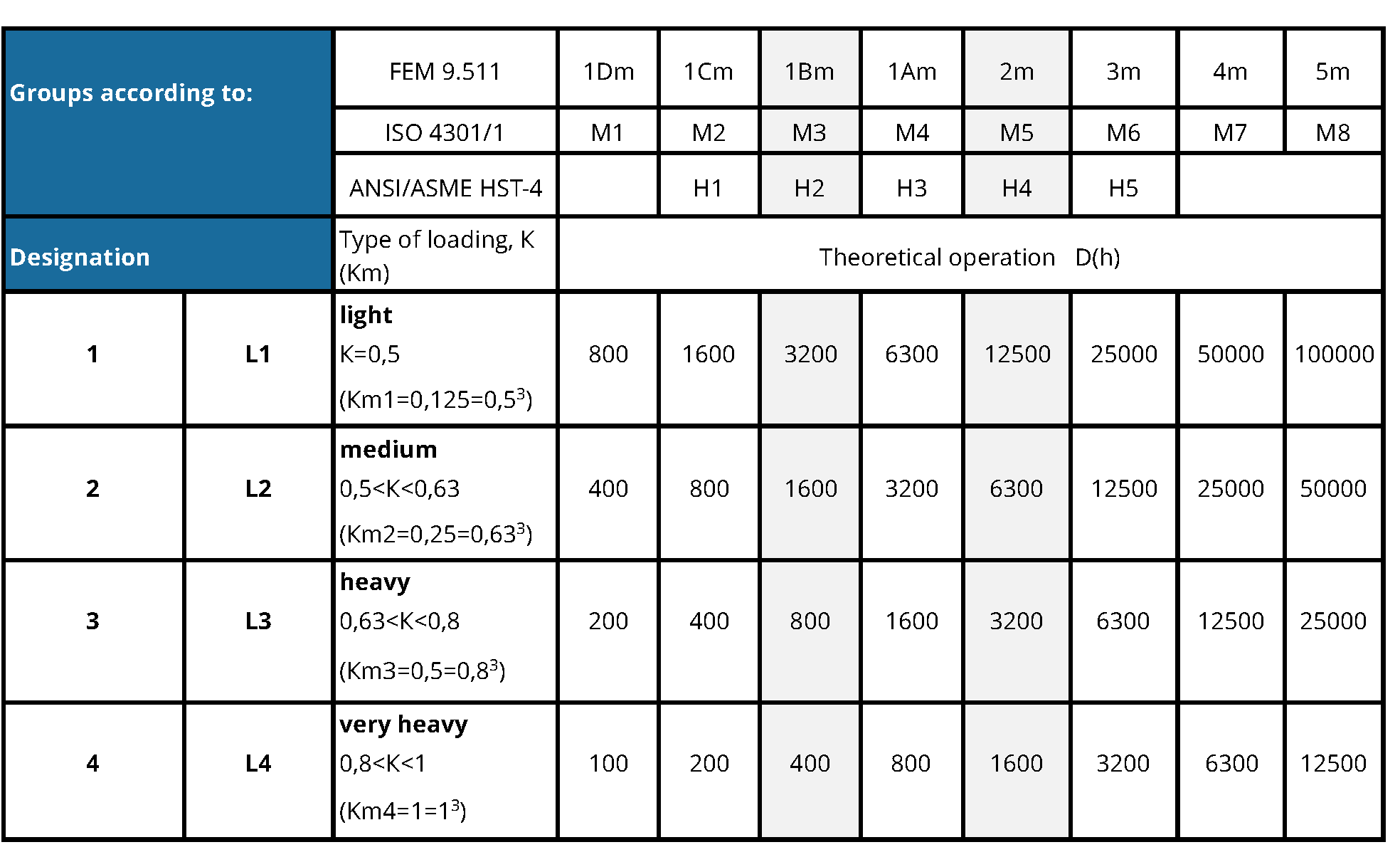

The interesting part is when we get to the chart below. When we start comparing how all this relates to measuring hoist life expectancy. The chart below shows a hoists life expectancy in hours compared to percentage of loading under each FEM and ASME category standard. Here is where we can get into the interesting commercial side, as commercially two hoists can have the same specs (capacity, lift speeds, etc), but if you look at the duty rating they can be worlds apart. Compare in the chart below the life expectancy between hoists in groups 1Bm ~ 2m. Life expectancy just two groups apart, 1Bm ~ 2m varies from 400 hour to 1,600 hour, that is 4x life.

That’s not to say that you always need a hoist rated in the higher end, many applications call for very little usage and do not require anything more. The best practice, is to calculate your actual usage requirement and then look for a unit to suit. With the cost of labor and parts though, its usually not a bad idea to fair on the higher side as it also allows you the peace of mind in case you need to ramp up production or there is a sudden upsurge in your shop.

We hope you enjoyed our article and found it useful. If you have any questions or comments please let us know below. If you are into formulas, we have included some here, or you can try the free FEM CALCULATOR from Swiss Chain Hoist Manufacturer GIS.